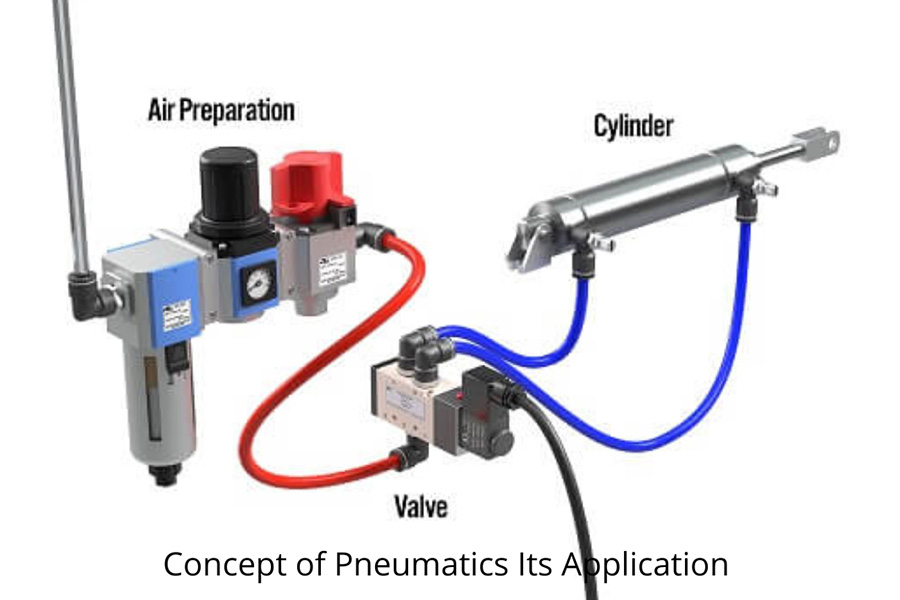

Pneumatics is a term that refers to systems that operate using the power of compressed air. These systems are used in various fields to provide mechanical motion and power. The basic working principle of pneumatic systems is that air is compressed and stored using a compressor, and then released in a controlled manner when needed. The released compressed air is used to do work through actuators such as pistons, valves, and other pneumatic components.

There are many advantages to using pneumatic systems. Some of these advantages include:

- Safe: Pneumatic systems are safer than electrical systems. There is no risk of explosion with air, and there is also no risk of electric shock with pneumatic systems.

- Clean: Pneumatic systems are cleaner than hydraulic systems. There is no oil or other contaminants in the air.

- Efficient: Pneumatic systems use energy efficiently. Compressed air can be stored and reused after work is done.

- Flexible: Pneumatic systems can be adapted to a wide variety of applications. Pneumatic actuators are available in different sizes and powers.

- Affordable: Pneumatic systems are more affordable than other automation systems.

Pneumatic systems are used in many different areas. The main areas of use are:

- Industry: Pneumatic systems are widely used in production lines, robotics, assembly lines, automation systems, air tools, and conveyor systems.

- Construction: Pneumatic systems are used in drills, hammers, sanders, and other construction tools.

- Medical: Pneumatic systems are used in dental instruments, ventilators, and other medical devices.

- Transportation: Pneumatic systems are used in truck brakes, airbags, and automatic doors.

- Agriculture: Pneumatic systems are used in spraying, fertilizing, irrigation, and harvesting.

Pneumatic systems are a versatile technology that can be used in many different areas. They have many advantages such as being safe, clean, efficient, flexible, and affordable. Therefore, pneumatic systems are an ideal choice for many different applications.