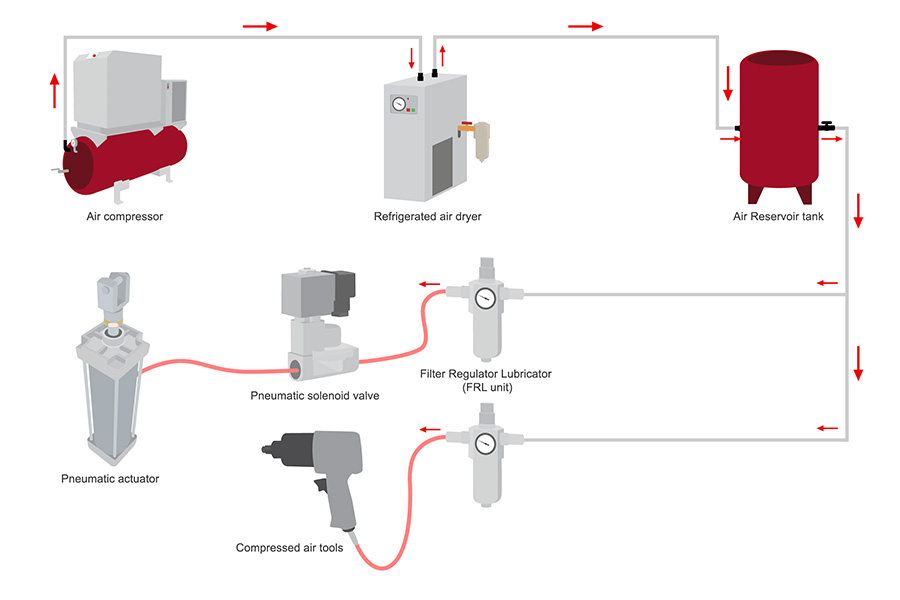

Pneumatic systems are systems that operate using the power of compressed air. These systems are used in many different areas to provide mechanical motion and power. The working principle of pneumatic systems is quite simple. Compressed air generated by a compressor is stored in an air tank and released in a controlled manner when needed to actuate actuators. These actuators then perform mechanical work.

There are many different components used in pneumatic systems. We can categorize these components as follows:

Air Preparation Components:

- Compressor: Compresses and pressurizes the air.

- Air Filter: Removes contaminants and particles from the air.

- Air Regulator: Adjusts the air pressure.

- Lubricator: Lubricates the air.

- Air Tank: Stores compressed air.

Control Components:

- Valves: Controls the flow of air.

- Pressure Gauges: Displays the air pressure.

- Sensors: Detects parameters such as air pressure, flow, or temperature.

Actuators:

- Pistons: Converts air pressure into linear motion.

- Diaphragms: Converts air pressure into circular motion.

- Motors: Converts air pressure into rotary motion.

Other Components:

- Pipes and Hoses: Allows the air to be transported.

- Fittings: Allows pipes and hoses to be connected to each other.

Different Types of Pneumatic Systems:

Pneumatic systems can be classified into different types according to their working principles and application areas. The main types of pneumatic systems are:

- Single-Acting Pneumatic Systems: In these systems, the piston or diaphragm moves in only one direction. The return is provided by a spring or other mechanical force.

- Double-Acting Pneumatic Systems: In these systems, the piston or diaphragm can move in both directions. Air is used for movement in both directions.

- Servo Pneumatic Systems: In these systems, pneumatic actuators are precisely controlled by a control system. Servo pneumatic systems are used in robotics and other applications requiring precise control.

The choice of pneumatic systems depends on the application and the required force and speed. Pneumatic systems are a versatile technology with many advantages. They are safe, clean, efficient, flexible, and affordable. Therefore, pneumatic systems are an ideal choice for many different applications.